Hot blast stove automatic control in staggered parallel operation

System composition

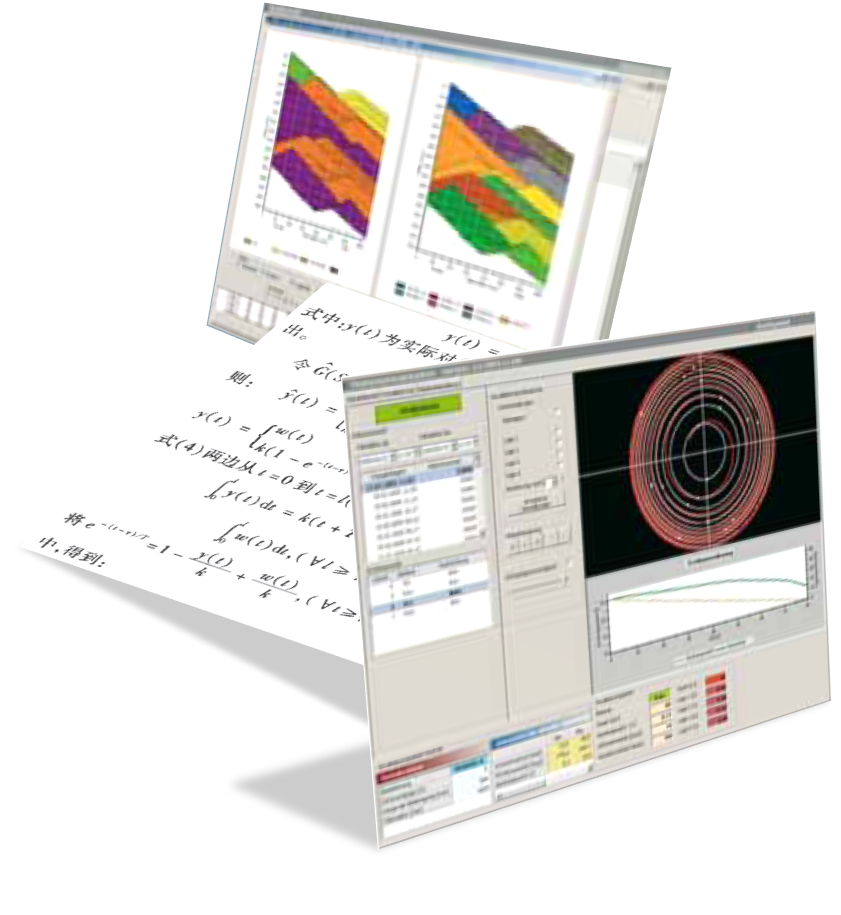

Numerical model of multi variable parameter hot blast stove

Hot blast stove is a big inertia and delay system, and the influence of thermal storage and send wind and many, including furnace capacity, heat storage body, a burner, gas calorific value, gas volume, gas preheating temperature, air, air humidity, heat loss of pipeline, and so on a number of factors, so in order to accurately and stably control the supply air temperature, we need through the establishment of accurate, multi variable parameters of hot blast stove digital model of heat storage and air supply trend forecast, according to the forecast results, with neurons matrix model deduction, control decision basis for combustion and air supply and change of the stove and other steps. AEMETEC with for many years in the industry, metallurgy, energy and other fields has accumulated a lot of experience, combined with the most powerful country level simulation control research center, together to build a rapid response, the data is automatically updated and optimized, with results accurate hot air furnace digital model. The model has been verified in the implementation of the automatic control system of the 5 blast furnace in Wuhan Iron and steel company.

Hot blast stove is a big inertia and delay system, and the influence of thermal storage and send wind and many, including furnace capacity, heat storage body, a burner, gas calorific value, gas volume, gas preheating temperature, air, air humidity, heat loss of pipeline, and so on a number of factors, so in order to accurately and stably control the supply air temperature, we need through the establishment of accurate, multi variable parameters of hot blast stove digital model of heat storage and air supply trend forecast, according to the forecast results, with neurons matrix model deduction, control decision basis for combustion and air supply and change of the stove and other steps. AEMETEC with for many years in the industry, metallurgy, energy and other fields has accumulated a lot of experience, combined with the most powerful country level simulation control research center, together to build a rapid response, the data is automatically updated and optimized, with results accurate hot air furnace digital model. The model has been verified in the implementation of the automatic control system of the 5 blast furnace in Wuhan Iron and steel company.

Neuron matrix model

After the establishment of the multi variable parameters of hot blast stove digital model, each variable into carrying model of high-speed computers (workstations or minicomputer), through a neuron matrix model deduction algorithm, is about the process of hot blast stove combustion, air supply and exchange furnace and predict the amount, the predicted amount and then fed with expert knowledge base of hot blast stove intelligent adaptive control algorithm, to achieve accurate wind and temperature control.

According to the expert knowledge base of intelligent adaptive adjustment algorithm

Through the implementation of the model neuron matrix is deduced to calculate decision parameters and can not be completely accurate embodiment of hot blast stove after long-term use, also need further refinement processing and calculation can be accurate control over the final air temperature, also these fine processing and calculating the data also feedback to the front of the multi variable parameters of hot blast stove digital model, with the model implementation of optimization and correction. AEMETEC in construction of an expert knowledge base, not only receive the abundant knowledge of the well-known Chinese Academy of engineering, ironmaking technology, design experts, but also absorb the valuable technology experts at the scene and operator's extensive experience, combining billion Bo for many years in the field of metallurgy superior control technology level, construct a set of international advanced level of control algorithm.

Because the air valve is not only large diameter, large inertia, but also in the whole trip in serious nonlinear, in both the opening and closing of the small angle is not very sensitive, and in the middle are too sensitive, so it must be able to accurately realize micro valve flap trimming, we use high power digital hydraulic cylinder can be accurately adjusted micro cold air regulation the valve opening as the actuator, combined into digital high precision cold air flow control valve and the precision cold air valve, not only the high precision positioning capability to ensure the accuracy of the valve, the output power is more important to ensure the reliability of the hydraulic cylinder, the other due to avoid driving motor driven mechanical space drive reducer the fretting, high precision, which is the fundamental guarantee of high precision stable wind temperature.

SIEMENS PLC system

World recognized outstanding industrial control equipment S7-300PLC not only to ensure the stable operation of a full set of systems, but also provides a large computing and information throughput and reliable logic control capability. Through industrial Ethernet or Profib-bus network, simple system into the existing control system of hot blast furnace.

Reference:

Visits: